I'm looking for...

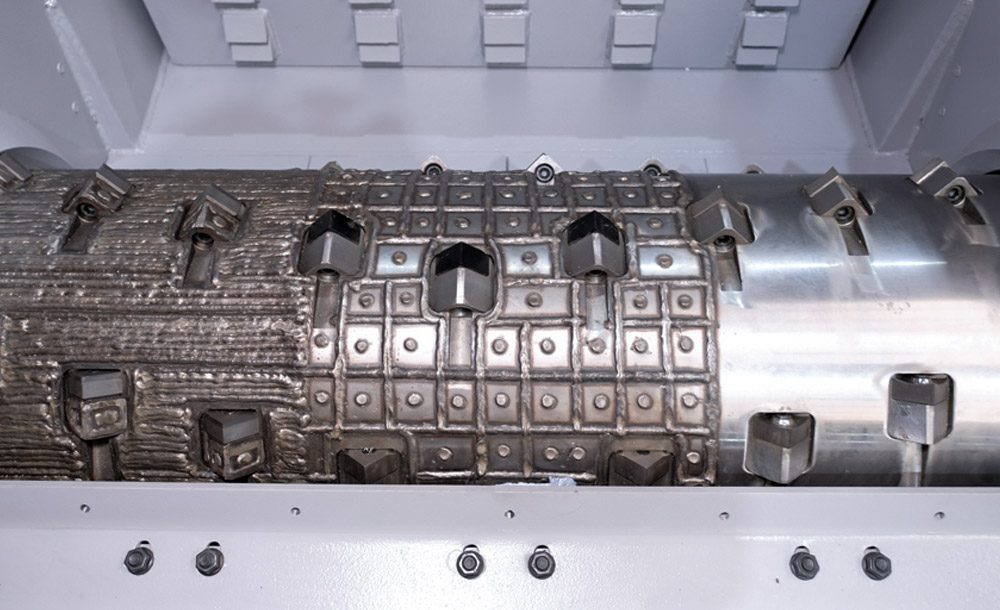

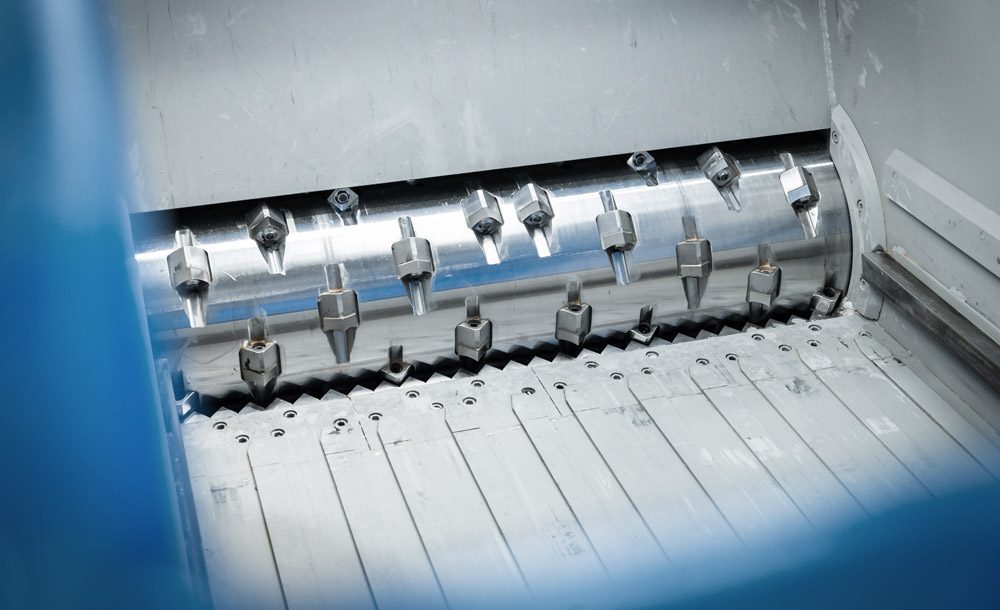

Hard facing / hard surfacing

For the use of grinders in the processing of particularly hard materials or heavy-duty applications, we recommend hard facing of the rotor.

Hard facing, for example with hard-surfacing welding electrodes, etc., significantly extends the service life by reducing the wear and tear on a rotor.

This prevents possible downtime due to unforeseen damage, which in turn has a positive effect on the overall service life of the machine. As a result, there is less machine downtime.

Hard facing can be retrofitted and refreshed as required and can be repeated several times. This virtually eliminates wear and tear on the cutting system. Positive side effect: Maintenance intervals can be extended and costs reduced. Hard facing thus provides economic advantages on several levels. We offer hard facing for used and new machines!

Your contact

Christian Ottenthal

Area Sales Manager spare parts and service

Languages: Deutsch, English

Holm Hentschke

Area Sales Manager

Languages: Deutsch, English

Sofien Rejeb

Area Sales Manager

Languages: Deutsch, English, Francais, Español, عربي