I'm looking for...

Two shaft shredder AMIS ARS 1200

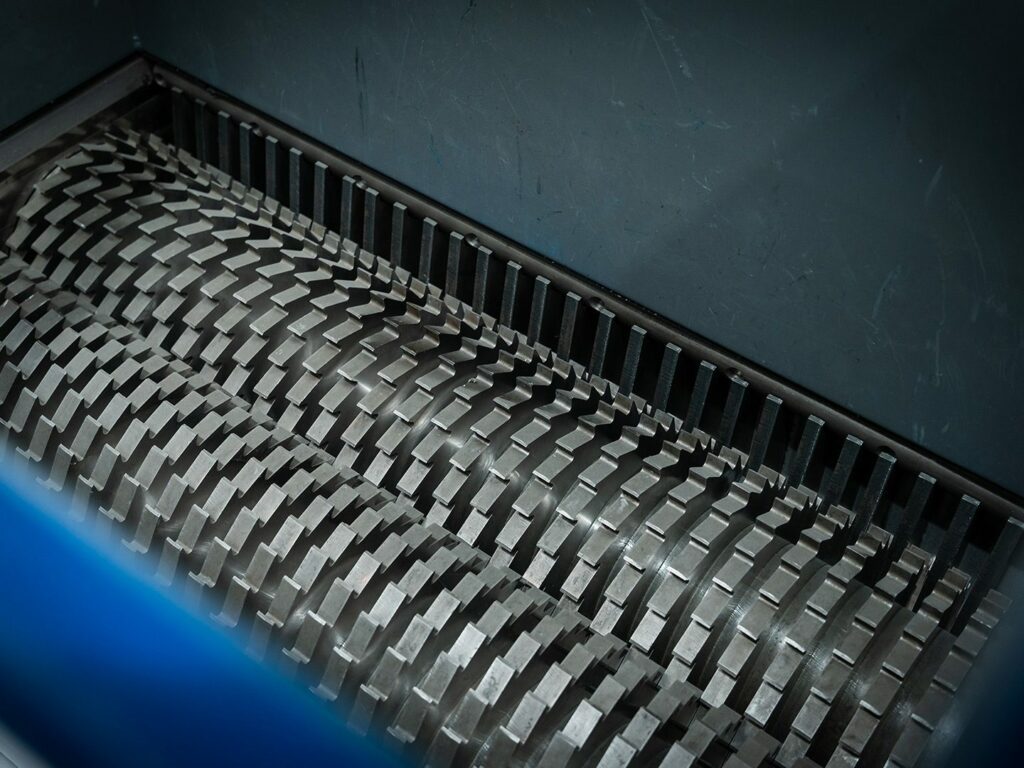

The AMIS two shaft shredder contains a CNC-finished, massive grind chamber which is completely, screwed in, making it easy to maintain. The machine housing, as well as its storage, are protected with deterioration rings or plates.

General description

The gear motor generates both six-edged working shafts, which can be provided with different, changeable cutting disks. Both of the working shafts are stored in big dimensional SKF- spherical bearings with lifespan greasing. Optionally, an automatic battery- charged continuously greaser can be built into the main bearing.

Special Features

To change the wear plates and the scraper, disassembling the machine housing is not necessary. Thanks to the horizontally divided storage plates the rotors, together with their storage, can be mounted and removed from the top — all of this in the shortest time.

Therefore, a rotor change with other cutting devices is executed easily and fast. The size of the grinding chamber can be adjusted with almost no effort through the screwed in machine housing construction. Thereby the motor assembly, gear size, fixture position and rotor drive speed can be adjusted accordingly.

Technical information

- Cutting room: 600 x 1200 mm

- Number of cutting discs: 60 pcs (Hardox)

- Cutting disc width: 19 mm

- Maximum cutting disc diameter: 295 mm

- Number of scraper: 2 pcs

- Drive capacity: 2 x 15 kW, 400 V, 50 Hz

- Weight: 2800 kg

Electric control

The machine is operated via the modern Simens S 7/1200- controller with progressive 7- inch touchscreen display.

Both gear motors are controlled, load dependant, via the revers circuit. Independent of the material and the application, three different control programs are given.

Use specific options

- adapted base frame

- special cone

- grinder with different tools and cutting

- discs (diameter, size, strength, form,

- material quality)

- different drive capacities

- different gear sizes with differing

- rotation speed