I'm looking for...

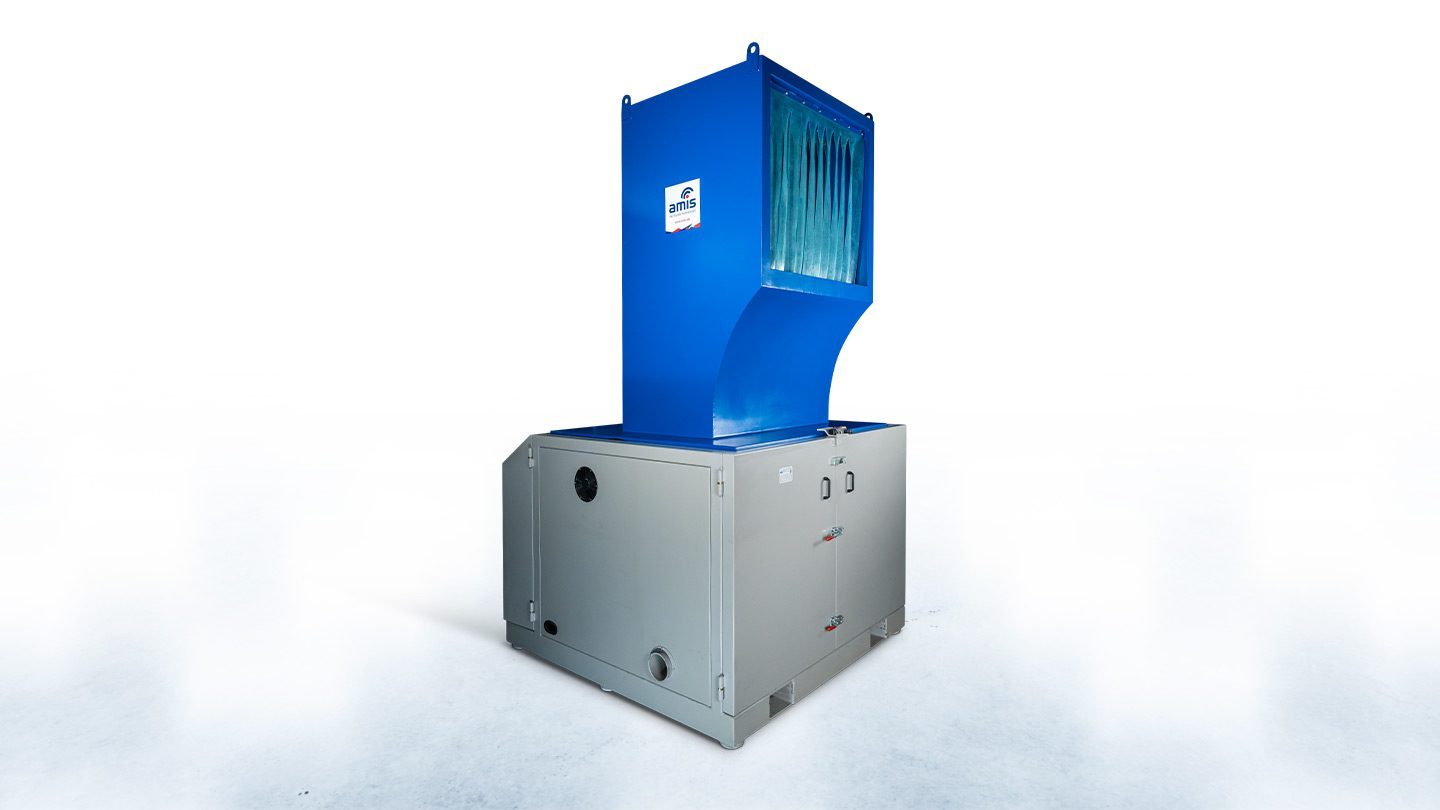

Compact soundproofed granulator ZERMA GSC

The design of the GSC granulators in terms of material and construction, offers the best sound dampening characteristics. The sound proof enclosure ensures easy and quick access to the cutting chamber during rotor/stator knife servicing and screen removal. The sound proof material used is based on the latest technological research.

General description

The sound proof enclosure ensures easy and quick access to the cutting chamber during rotor/stator knife servicing and screen removal. The sound proof material used is based on the latest technological research.

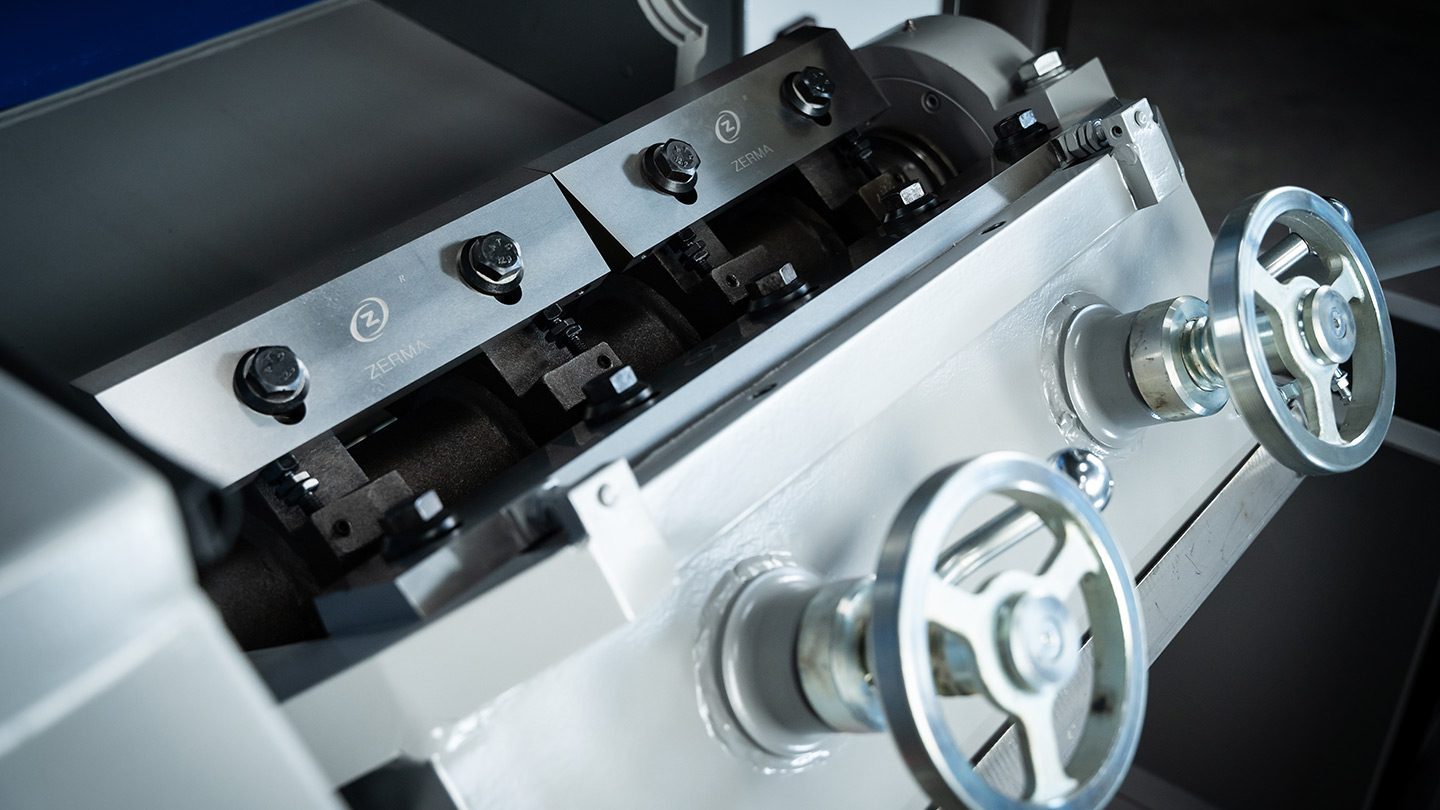

The completely welded cutting chamber in conjunction with the ”V” type rotor design (except GSC 300/300) ensures dependability in operation and universal applications use. The cutting geometry of the GSC series allows material feed injection even with voluminous types of material. The complete GSC series line achieves a high quality granulate irrelevant of the material type such as injection moulded parts, blow moulded parts, profiles, sheet, film, etc.

The design of the GSC granulators in terms of material and construction, offers the best sound dampening characteristics combined with quick and easy access to the inner machine parts for servicing and maintenance work. The granulator is built as a compact unit that can be moved or transported easily by a fork lift or standard lifting device.

Features and Advantages:

- Cutting chamber wear plates are standard

- Outboard Rotor Bearings

- Drop Down Screen Cradle

- Reversible screen

- “Clam Shell” Opening of Upper Cutting Chamber.

- “V” Cut Rotor/Stator Knife Configuration

- Double Sided Stator Knives

- Compact sound proof design

Applications

The cutting geometry of the GSC series allows even voluminous materials to be ground.

The complete GSC series line achieves a high quality regrind independent of the material type or form such as injection moulded parts,blow moulded parts, profiles, sheets, film, etc.

The integrated sound proofing makes it possible to easily place the machine in existing operations.

With different rotor designs and a wide variety of options the machines can be tailored for many different applications.

Specifications

GSC 300

| Type | 300/300 | 300/600 | 300/1000 |

|---|---|---|---|

| Rotor diameter (mm) | 300 | 300 | 300 |

| Rotor width (mm) | 300 | 600 | 1000 |

| Drive capacity (kW) | 7.5 | 18.5 | 18.5 |

| Rotor knifes (rows) | 3 | 3 | 3 |

| Stator blades (rows) | 2 | 2 | 2 |

| Screen size (mm) | > 6 | > 6 | > 6 |

| Effective working area (mm) | 400 x 290 | 400 x 590 | 400 x 990 |

| Weight approx. (kg) | 1200 | 1400 | 1850 |

The 300 series GSC machines are mainly used in inline operations for processing of rejected products, or runners and sprues.

GSC 500

| Type | 500/500 | 500/700 | 500/1000 | 500/1400 |

|---|---|---|---|---|

| Rotor diameter (mm) | 500 | 500 | 500 | 500 |

| Rotor width (mm) | 500 | 700 | 1000 | 1400 |

| Drive capacity (kW) | 30 | 37 | 45 | 45 |

| Rotor knifes (rows) | 3 or 5 | 3 or 5 | 3 or 5 | 3 or 5 |

| Stator blades (rows) | 2 or 3 | 2 or 3 | 2 or 3 | 2 or 3 |

| Screen size (mm) | > 6 | > 6 | > 6 | > 6 |

| Effective working area (mm) | 560 x 500 | 560 x 700 | 560 x 990 | 560 x 1400 |

| Weight approx. (kg) | 2200 | 2500 | 3000 | 5500 |

The 500 series GSC machines are mainly used in inline operations or small central granualtors for processing of medium sized hollow thin walled products, or runners and sprues.

GSC 700

| Type | 700/700 | 700/1000 | 700/1400 |

|---|---|---|---|

| Rotor diameter (mm) | 700 | 700 | 700 |

| Rotor width (mm) | 700 | 1000 | 1400 |

| Drive capacity (kW) | 45 | 55 | 55 |

| Rotor knifes (rows) | 5 or 7 | 5 or 7 | 5 or 7 |

| Stator blades (rows) | 2 or 3 | 2 or 3 | 2 or 3 |

| Screen size (mm) | > 6 | > 6 | > 6 |

| Effective working area (mm) | 720 x 700 | 720 x 990 | 720 x 1400 |

| Weight approx. (kg) | 4200 | 5100 | 6200 |

The 700 series GSC machines are mainly used as central granualtors for processing of large injected or blow moulded products as well as film. The integrated sound proofing makes it possible to easily place the machine in existing operations.