I'm looking for...

Pulverizer ZERMA PM

Typical applications are the pulverizing of granulates from plastic profiles, tubes, sheets, edge trim materials, film waste and also products from the food, chemical and pharmaceutical industry.

General description

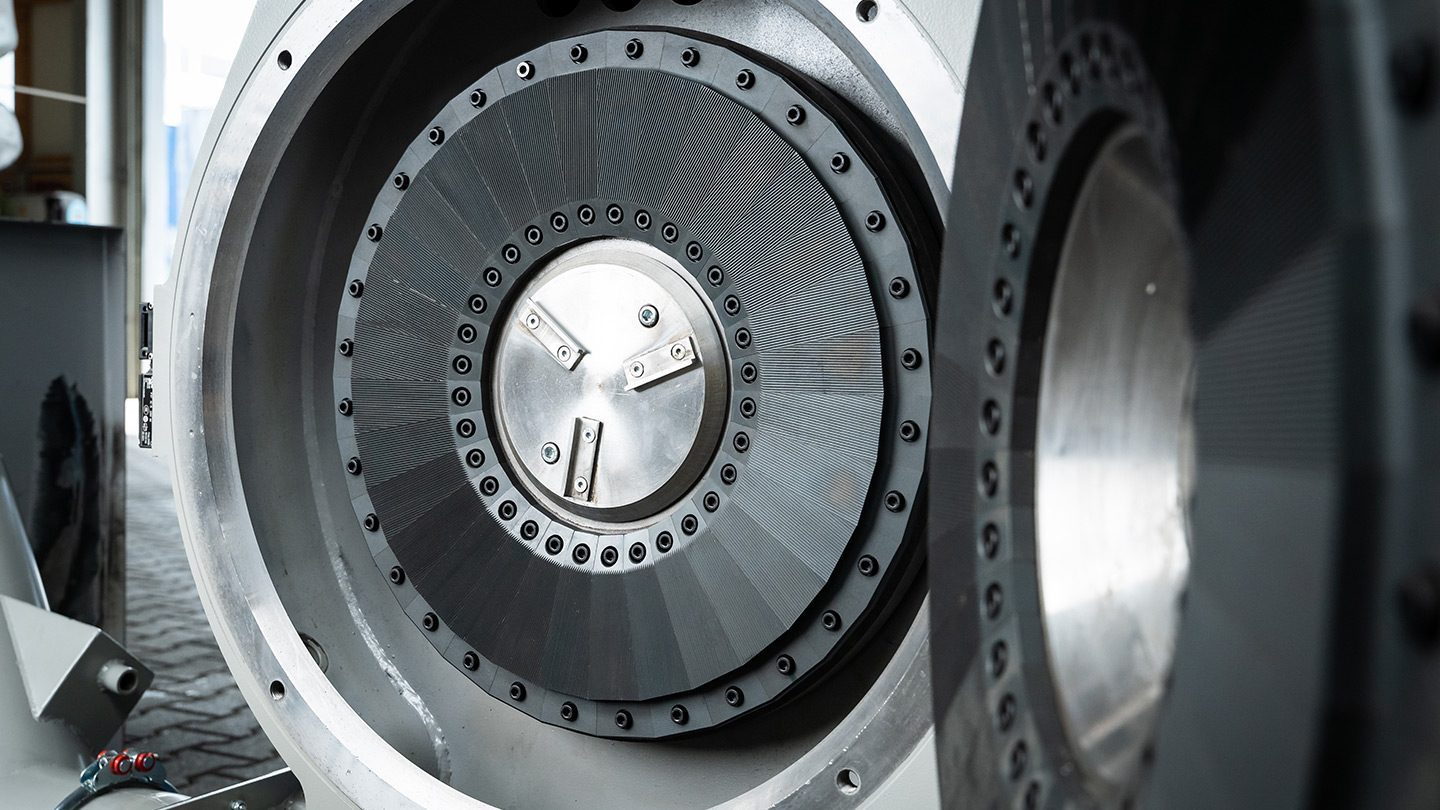

The disc pulverizers of the PM series are available with disc diameter from 300 to 800 mm. These pulverizers are high speed, precision grinders for the processing of medium hard, impact resistant and friable materials.

The material to be pulverized is introduced through the centre of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc.

Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system.

Depending on the application the machines can be equipped with one piece grinding discs or grinding segments.

Applications

One of the main fields of use for the ZERMA PM Pulverizers is the pulverization of PVC regrind in pipe and profile recycling.

Working in line with a shredder and granulator to have a balanced and efficient system to handle in house production waste.

Another application is the grinding of PE for Rotomolding applications, here the PM Pulverizer is used in the production process to create the powder needed in the process.

In this process a screening machine is necessary to ensure the right output size, distribution and flow properties of the ground material.

Specifications

| Type | 300 | 500 | 800 |

|---|---|---|---|

| Discs diameter (mm) | 300 | 500 | 800 |

| Drive capacity (kW) | 22 | 55 | 90 |

| Weight approx. (kg) | 900 | 1800 | 2500 |

| Throughput approx. (kg/h) | 50 – 250 | 100 – 500 | 200 – 800 |