I'm looking for...

Single shaft shredder ZERMA ZHS

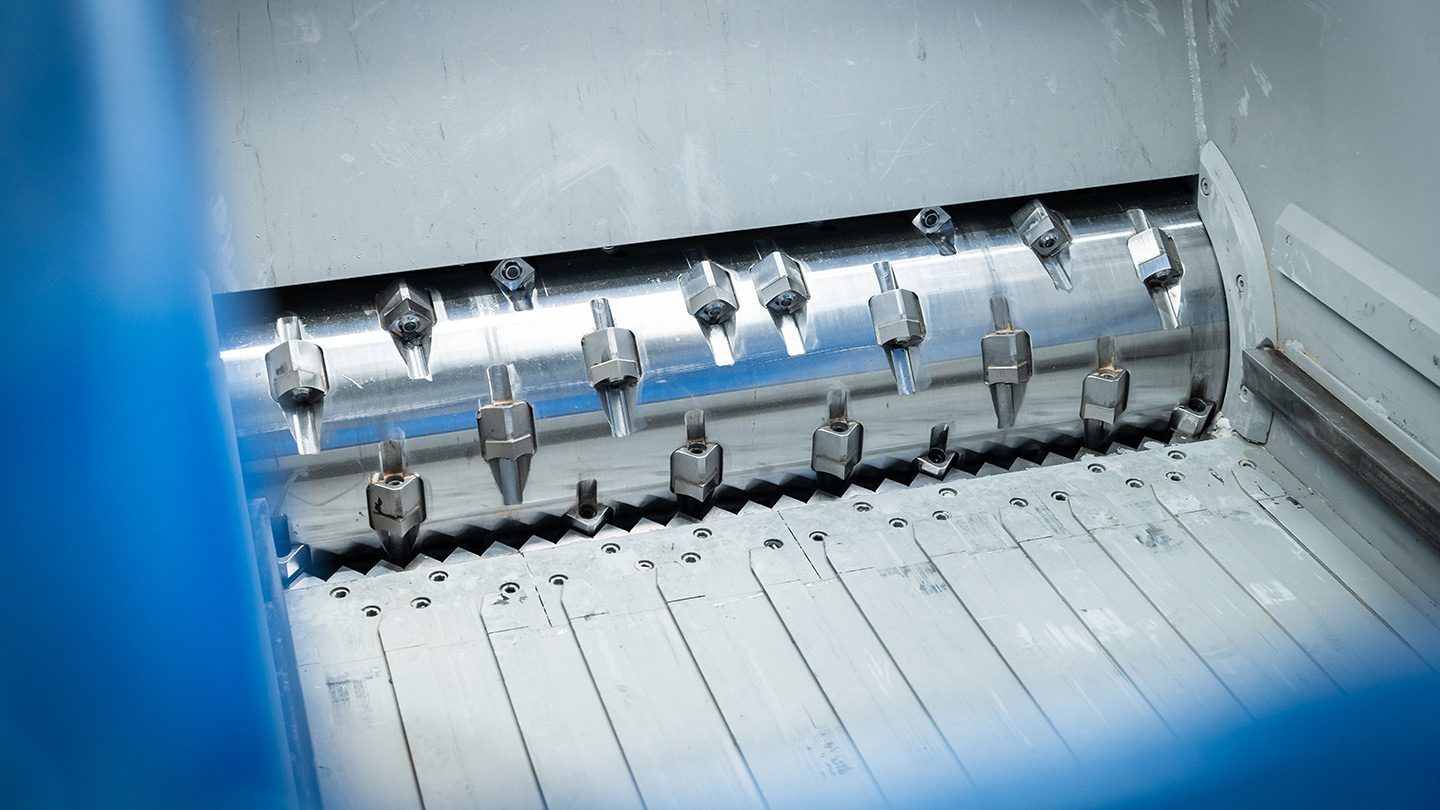

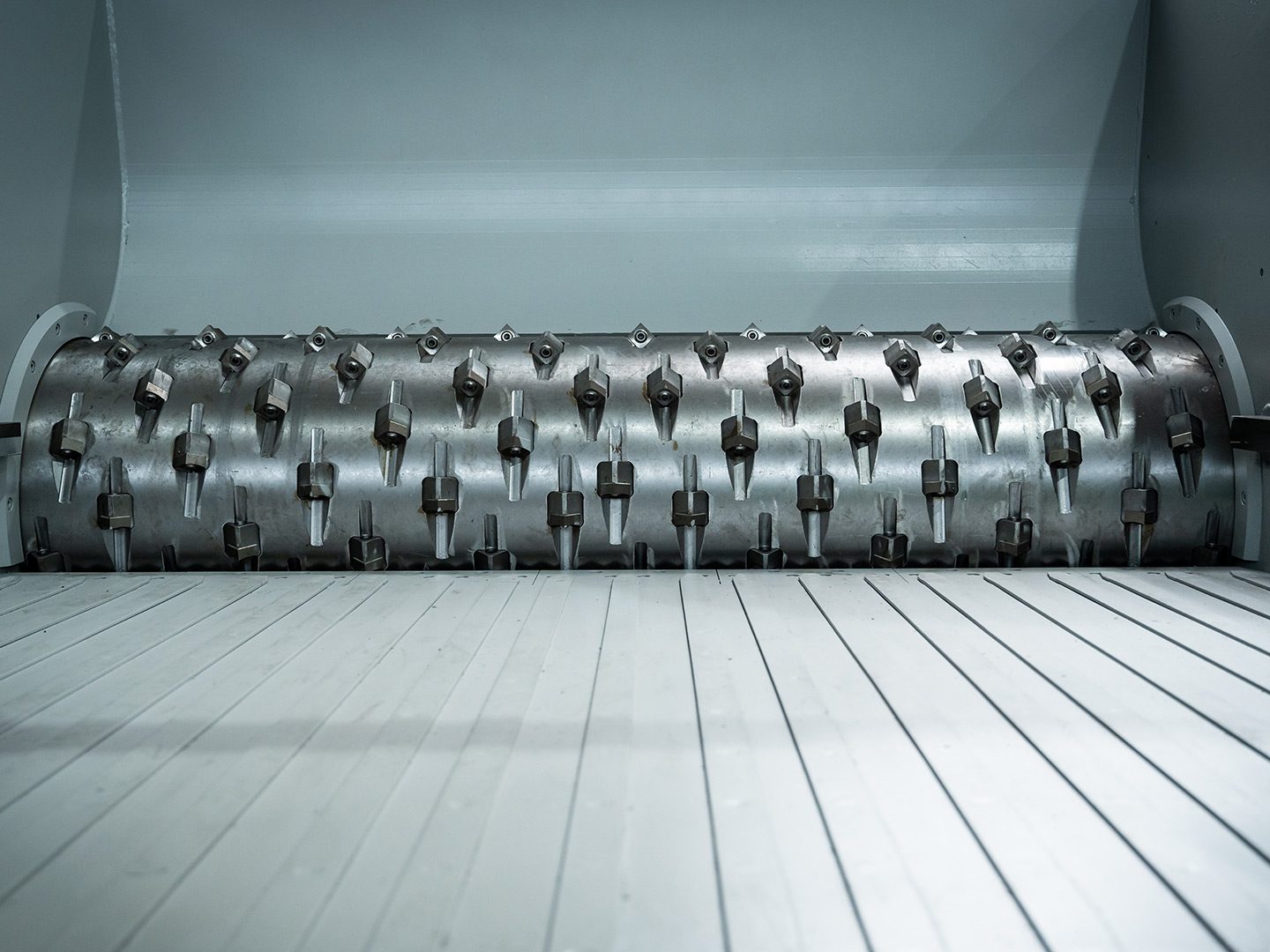

ZERMA ZHS shredders are single shaft shredders featuring an angled hydraulic ram suitable for a wide range of material shapes and sizes. The ZHS shredders are equipped with a E style rotor and knifeholder fixing system.

General description

ZERMA ZHS shredders are single shaft shredders featuring an angled hydraulic ram suitable for a wide range of material shapes and sizes. The ZHS shredders are equipped with a E style rotor and knifeholder fixing system.

The final size of the material is determined by the screen which can easily be changed based on requirements. The ZHS shredder can be tailored to individual requirements, which includes different drive powers, knife configurations as well as discharge options.

- Large feeding hopper

- Robust welded steel construction

- Low speed operation

- Advanced rotor / knife mounting System

Applications

The ZHS series of single shaft shredders are mainly used in the industry to achieve a economic recycling of plastics to wood, paper, and general waste streams.

The machines have been engineered for strength and reliability in daily operation.

These shredders can easily be integrated into complete lines with other ZERMA products and accessories such as belts, granulators, etc.

Specifications

ZHS 600-1100

| Type | 600 | 850 | 1100 |

|---|---|---|---|

| Rotor diameter (mm) | 400 | 400 | 400 |

| Rotor width (mm) | 560 | 840 | 1120 |

| Rotor speed (rpm) | 100 | 100 | 100 |

| Drive capacity (kW) | 18.5 / 22 | 30 | 37 |

| Rotor knifes (pcs) | 13 / 26 | 20 / 40 | 27 / 54 |

| Stator blades (rows) | 1 | 1 | 1 |

| Ram feeder drive (kW) | 1.5 | 1.5 | 1.5 |

| Screen size (mm) | > 40 | > 40 | > 40 |

| Cutting chamber volume (m3) | 0.6 | 1.25 | 2 |

| Effective working area (mm) | 520 x 470 | 800 x 820 | 1080 x 1040 |

ZHS 1500 – 2600/600

| Type | 1500 | 1700 | 2000 | 2600 | 2600/600 |

|---|---|---|---|---|---|

| Rotor diameter (mm) | 400 | 400 | 400 | 400 | 600 |

| Rotor width (mm) | 1400 | 1700 | 1960 | 2520 | 2520 |

| Rotor speed (rpm) | 104 | 104 | 104 | 104 | 104 |

| Drive capacity (kW) | 90 / 110 | 75 | 110 / 2 x 90 | 2 x 90 | 2 x 90 |

| Rotor knifes (pcs) | 34 | 82 | 48 | 62 | 124 |

| Stator blades (rows) | 1 x 5 | 1 x 6 | 1 x 7 | 1 x 9 | 1 x 9 |

| Ram feeder drive (kW) | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Screen size (mm) | > 40 | > 40 | > 40 | > 40 | > 40 |

| Cutting chamber volume (m3) | 3.6 | 4.7 | 5.5 | 7.2 | 8.9 |

| Effective working area (mm) | 1360 x 1430 | 1640 x 1550 | 1920 x 1550 | 2480 x 1550 | 2480 x 1550 |